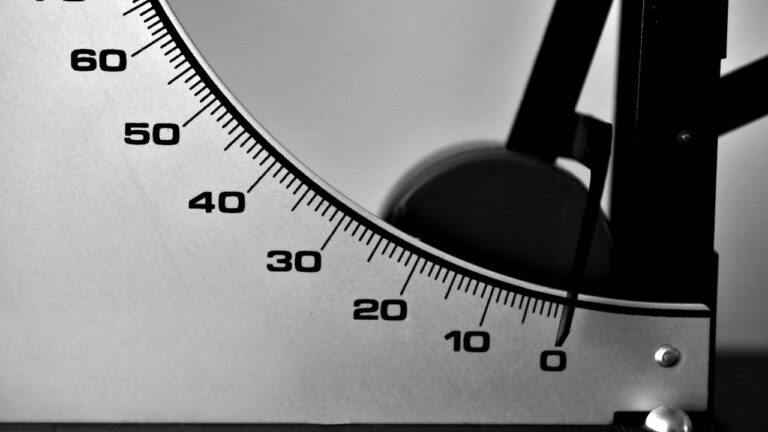

Equipment calibration plays a pivotal role in ensuring Irish tech firms maintain the highest standards of accuracy and reliability across their operations. As technology becomes more complex and regulations grow stricter, regular calibration is essential for organisations aiming to deliver high-quality products, assure compliance, and protect their reputation. With precise measurements at the core of innovation and production, Irish tech companies rely on well-calibrated equipment to remain competitive and trusted in both local and international markets.

Why Calibration Is Critical for High-Tech Operations

Irish technology firms operate in sectors where precision is not simply advantageous but essential. Semiconductor manufacturing, medical device design, robotics, and materials testing all demand highly accurate instruments to ensure reliable outcomes and safety.

For high-performance environments, even a small error can ripple into bigger issues. That’s why keeping the equipment calibrated is important not just for accuracy, but for credibility and compliance.

Equipment out of calibration can generate faulty data, leading to incorrect decisions and potential safety risks. This can be particularly problematic in medical technology, where patient outcomes may be impacted.

Strict industry regulations in Ireland and across Europe also necessitate consistent calibration. Firms must demonstrate that their measurement tools are well maintained and produce verifiable results, both for their customers’ trust and for regulatory audits.

Through regular calibration, companies reduce variability, improve repeatability, and maintain the high standards expected in advanced technology sectors. This attention to accuracy is equally critical when developing early-stage innovations – just as explored in discussions about why precision matters in tech startup prototyping. This diligence supports product reliability and the long-term reputation of Irish innovation.

Meeting Industry Standards Through Professional Calibration Services

Irish tech firms often operate under strict regulations, especially in sectors governed by international standards such as ISO 9001, ISO 17025, or Good Manufacturing Practice (GMP). Professional calibration services play a crucial role in helping companies achieve and maintain these certifications.

Accurate calibration ensures that all equipment performs within defined tolerances, reducing the risk of measurement errors and non-compliance. These standards demand precise, repeatable results that only properly calibrated equipment can provide. Any deviation could lead to failed inspections or costly recalls.

Quality audits frequently require detailed documentation and full traceability of calibration activities. Companies must maintain records that demonstrate regular and systematic calibration has occurred. This documentation is essential for proving compliance and protecting against potential audit findings.

To ensure consistent performance in complex environments, many companies rely on qualified technicians at Calibration Lab for regular calibration and compliance support.

Traceable calibrations not only satisfy regulatory requirements but also reinforce a culture of quality and accountability within the organisation. In regulated industries, this attention to detail is non-negotiable for continued operation and market access.

The Overlooked Role of Calibration in Electrical Safety

Irish tech firms often rely on advanced equipment for testing power systems and designing electronics. When calibration is neglected, measurement errors can lead to incorrect results, creating hidden electrical hazards within operating environments.

Improperly calibrated devices may fail to detect electrical faults or produce inaccurate readings, increasing the risk of shock or equipment failure. This is critical in workplaces where precise voltage and current measurements are essential for safety.

Equipment failures caused by calibration issues frequently result in unexpected downtime and costly repairs. Sensitive components may become damaged if exposed to incorrect currents, further impacting productivity.

Many firms fail to realise that outdated equipment and poor documentation can lead to electrical safety compliance issues, particularly when inspections or certifications are required.

For companies handling regular electrical inspections, properly calibrated instruments help ensure compliance with Irish safety standards and regulations. By maintaining up-to-date calibration records, firms strengthen both workplace safety and audit readiness.

Common Equipment That Requires Regular Calibration in Tech Firms

Many Irish tech firms rely on precise measurements for quality and compliance. Among the most frequently overlooked tools are oscilloscopes, which should be calibrated at least once every twelve months to maintain accuracy in electrical signal testing.

Signal generators are vital for simulating electronic signals during development and repair. These instruments, too, generally require annual calibration, though high-usage environments may benefit from more frequent reviews.

Pressure sensors support various automated systems, from manufacturing robotics to HVAC controls. Regular testing, ideally every six to twelve months, helps ensure that these sensors continue to provide reliable readings.

Temperature controllers are another cornerstone of controlled environments, especially in electronics assembly and laboratory settings. A proper calibration interval ranges from six months to a year, depending on operational demands.

Firms often overlook the need for calibration of digital multimeters and laser measurement tools, both of which underpin daily troubleshooting and alignment activities. Scheduling these at least annually helps reduce the risk of small measurement errors accumulating over time.

Environmental sensors monitoring humidity and particle levels, commonly found in cleanrooms or data centres, should not be ignored. Their calibration, typically required every six months, protects the integrity of sensitive processes.

Building a Culture of Accuracy and Operational Confidence

Embedding calibration deeply within a company’s daily operations helps create a sense of trust both inside the organisation and among its clients. When calibration is prioritised, employees know that the data and results they handle are dependable.

Transparent tracking of calibration dates reduces the risk of oversight. Assigning clear responsibility for each piece of equipment encourages accountability and fosters a sense of ownership among staff. This clarity leads to fewer errors and smoother workflows.

Seeing calibration as a strategic asset can differentiate Irish tech firms in a crowded market. External partners are more likely to trust an organisation that demonstrates disciplined attention to accuracy and reliability through consistent calibration practices.

Establishing systematic calibration routines also instils operational confidence. Staff can rely on equipment performance, helping teams to focus on innovation rather than troubleshooting avoidable issues.

Conclusion

Equipment calibration underpins accuracy and trust in Irish technology firms, supporting both product quality and operational efficiency. Continuous attention to calibration enables firms to meet international standards, protect personnel, and reduce costly mistakes. Relying on skilled professionals, Irish tech companies safeguard their reputation and ensure the dependability of their innovations in a competitive global marketplace.